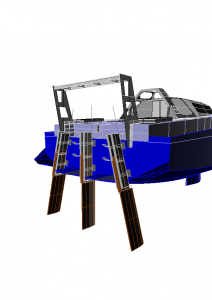

Sonabia 2 is equipped with 3 lifting rudders mounted at the stern.

Under sail: 2 lateral rudders

Motoring or sailing in ice: central rudder only

Maneuvers : 3 rudders

Hoisting the rudders

The rudders are hoisted manually to change configuration. The operation takes about 5 minutes for each rudder. You also hoist the rudders to remove packs of seaweeds, for maintenance...

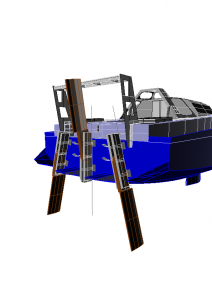

In case of impact

There are 2 safety mechanisms to block the rudders in low position (a blocking rope and a removable plate). In case of impact, the safety breaks and the rudder lifts. The damage is minor.

Replacement and maintenance

A single person can replace a rudder without help, boat in the water. Careening is also easy: you only have to lift the rudder

No need for a spare rudder

In case of broken rudder, the boat can sail with 2 out of 3 rudders, any of them The boat can even sail with a single rudder in case of emergency.

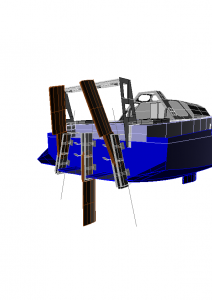

Simplicity of construction

The rudders are made of laminated wood (epicea) with a protection of fiberglass epoxy. The underwater profile is straight, a little loss of performance, but a huge benefit in simplicity.

History

The architect´s proposal was 2 elliptical rudders. Good for performance, bad for maintenance. There were hollow rudders, a glass epoxy shell filled with epoxy foam. The construction is expensive and time demanding. At the time I also had to find a solution for maneuvers. High hull, rudders and propeller close to the stern: not good for maneuvers. A bow thruster was discarded (complication, cost, weak point in the hull). So I decided for a third rudder behind the propeller (a common patch in expedition sailboats). I was about to add a small rudimentary rudder, but an acquaintance remarked that building 2 or 3 identical rudders did not make a big difference. So, 3 lifting rudders. I discarded the elliptical profile but I kept the hollow rudder construction. During the first transatlantic sailing (2021), the rudders gave problems. Weak point at the waterline (my fault), deficient blocking system (architect´s proposal, but my fault: I had been warned against it). For the first antarctic trip (2022), I used emergency rudders made of plain, green wood 75mm thick, built by a friend at Puerto Williams (thanks, Pascal " El Shov"). They worked very well and they served as a model for the definitive rudders.

Photo fokker triplane: Don Bay, pinterest.