A few videos

First Ironman in Deception Island: Connor Emeny

Instagram reels by David Cossio Sánchez and Connor Emeny

https://www.instagram.com/p/C7P51MiuvwC/

https://www.instagram.com/reel/C53-Z55S9gD/

A few videos

Instagram reels by David Cossio Sánchez and Connor Emeny

https://www.instagram.com/p/C7P51MiuvwC/

https://www.instagram.com/reel/C53-Z55S9gD/

In a former post, we disclosed the fuel consumption for SV Sonabia 2 in comparison with passenger ships.

the difference is stunning: 64 g of diesel fuel per person and nautical mile * on Sonabia 2 vs. 320 g on a passenger ship, in the best case.

*: 1 nautical mile = 1.852 km

In this post, we compute the complete carbon footprint of an Antarctic expedition on SV Sonabia 2.

Carbon footprint per person on a 3 weeks trip Ushuaia-Antarctic-Ushuaia,

diesel fuel consumption per person: 93kg, footprint 248.7 kg of CO2. 1 kg of diesel produces 2.68kg of CO2 equivalent. propane gas for cooking per person: 2kg, footprint 6kg of CO2. 1 kg of propane produces 3kg of pure CO2. TOTAL 255kg of CO2 per person food and other personal supplies are not counted (would be the same if you stay aground). the transportation of fuel and gas to Ushuaia is not counted. measured on the 2 Antarctic expeditions of season 2023-2024.

Air travel to and from Ushuaia considering 3 European destinations: Madrid, Paris, London

Madrid: 12.427 km, 1347 kg of CO2 (Madrid-Buenos Aires-Ushuaia) Paris: 13.440km, 1437 kg of CO2 (Paris-Buenos Aires-Ushuaia) Londres: 13.669km, 1580 kg of CO2 (London-Madrid-Buenos Aires-Ushuaia) source: ICAO carbon emission calculator. Round trip, tourist class.

FIRST CASE: backpackers and travelers: you are already in Ushuaia.

Second case: air travel from Madrid / Paris / London

The air travel is the same, but there is a marked difference on the sailing expedition itself

The minimal carbon footprint for a typical trip on a passenger ship is:

We consider a 1500 nautical miles trip (2778 km), a fuel comsumption of 320g per person and nautical mile (optimistic) and that the ship only uses light diesel fuel (very optimistic: many ships still use heavy fuel oil, which is more polluting).

According to your diet, the carbon footprint of your food for a full year is:

Estimates for the USA. Source: Afrouzi et al. (2003), Result in Engineering Vol 18. Warning. the carbon footprint estimates of the aliments are culturally biased: they only consider the industrial food available in the USA: meat,vegetables, etc.

2024 05 29 – Like every year we offer a low-cost trip to Antarctica for backpackers and travelers.

The trip is aimed at people that are easy going and with the spirit of adventure. Aboard, all tasks are done in common.

The crew (2 persons) is professional and experienced in sailing in the southern latitudes.

You will share 2 double cabins with separable berths and a single cabin.

2 possible departure dates: last week of November 2024 or 1st week of January 2025.

Departure from Ushuaia, Argentina or Puerto Williams, Chile , to be determined.

There is a 30% discount on our normal cost. Contact us for details and compare with other boats!

Feel the expedition!

https://www.instagram.com/reel/C7P51MiuvwC/

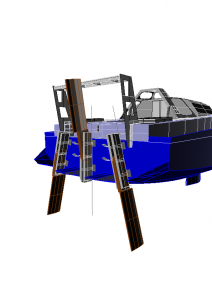

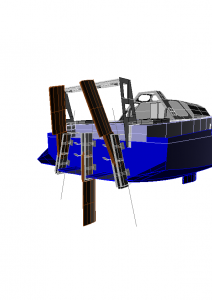

keel down, draft 2.90m keel up, draft 1.40m

total height 3.05m, total weight: 3.4 tons.

bulb : vertical shape, width 43cm, height 75cm, length 1.56m.

In open sea, stability in big waves and capacity to sail close to the wind.

The heavy, deep keel and the wide hull provide a high stability (the “righting moment”).

In coastal sailing, capacity to ground and get free easily.

The sturdy construction and the massive bulb allow to hit underwater rocks without damage.

The vertical lifting system allows to free the keel in any condition, grounded in rocks or mud, boat inclined or straight etc.

Why not a rotating keel?

A rotating lifting keel (or board) has to be flat to fit into the hull, therefore it is prone to bending in case of lateral impacts.

A vertical lifting keel stops the boat immediately on an obstacle, whereas with a rotating keel the boat may keep on going and ground completely.

keel structure: steel planks keel shape: fiberglass epoxy

The keel is embedded in the girders, within very thick grass epoxy walls (thickness up to 110mm).

The keel is supported by 3 steel rods (main rod:60mm diameter).

Electric industrial capstan, using a 8mm dyneema rope with a 8 to 1 hoist and high load blocks

The hauling system is oversized: capstan safety factor 1.7 (in addition to its internal safety factor), rope resistance 6000kg, blocks 4000kg each.

A safety rope holds the keel in mid position (in addition with the capstan internal clutch) when necessary.

For open sea sailing, blockers hold the keel in position in case of capsizing.

For coastal sailing, 4 planks made of polyethylene (not shown here) absorb the impacts.

On February 21, 2024, Connor Emeny completed the first Iron Man in Deception Island, Antarctica, in a little less than 33 hours.

Picture : Connor Emeny, Melchior Islands, February 2024.

This outstanding performance took place in Telefon Bay, a zone of volcanic ground, free from animals and vegetation.

The rules of the Antarctic Treaty (guidelines No 20) have been strictly followed, no damage to the flora and no interference with the animals.

Connor used a fat-wheeled bike, that left no traces on the rocky terrain. However the fat bike is slow and effortful, unlike the thin-wheeled bicycles used in a classical Iron Man.

At 0500AM, Connor swam more than 2 nautical miles (3.9km) in frozen waters. He took 30 minutes to warm up and regain his strength. Then he started biking for 180km. Finally Connor completed a 42km running..

Connor completed his Iron Man in a little less than 33 hours.

Previously, Ander Hofman ran an Iron Man in the New Shetlands in February 2020, but he was interrupted by a blizzard during 27 hours. He resumed after this break and his total time was 72 hours.

Connor Emeny, first to complete an Iron Man on 7 continents

Sonabia 2 and its crew were proud to help Connor in this project.

The trip…

Diaporama by David Cossio Sánchez

Diaporama by David Cossio Sánchez

A few videos from our trip to Antarctica on Sonabia 2, February 2023

The Portal of Dreams, by Carlos Guevara Vivanco, on Sonabia 2.

Gold Winner at European Photography Awards.

Lemaire Passage

Gerlache Strait

Chilean base Gonzalez Videla, Paradise Bay

Argentinian Base Almirante Brown, Paradise Bay

Enterprise Island

pictures: Cincinnati Zoo Blog, Animal Activist Watch

In 2021, Sonabia 2 crosses the Atlantic from Hendaye, France to Puerto Williams, Chile. Then COVID allowing, down to Antarctica.

At the time of selecting the crew mates, we said YES to anybody.

We did not care about experience, we just accepted acquaintances that were congenial and motivated.

It turned out to be a bad decision.

The 3 crew mates were inexperienced in long oceanic sailing.

They were warned about the difficulties, long time in open sea, night watches, and most important heavy weather in the roaring forties.

About the Antarctic, they were warned about the demanding Drake Passage, and told that navigation in the Antarctic was relatively easy, in comparison.

All of them said ” yes”, but none of them really understood what was expecting them.

A nice lady, in her sixties. She sailed to Cape Horn on Sonabia but she was totally ignorant about oceanic sailing. In her mind it was ” the cruising of love”.

A nice lady, in her sixties. She sailed to Cape Horn on Sonabia but she was totally ignorant about oceanic sailing. In her mind it was ” the cruising of love”.

Before leaving, she complicated the preparation with her whims, e.g. Irish tea, kilos of cocoa (never consumed), a larger pillow (never used), and so on.

In open sea, well… Inside, she was bumping everywhere, outside, she was unaware of the sea conditions, dangerous or not. Instead, she had irrational fears. And she was quite controlling.

Little pig No 1 disembarked in Canarias.

A congenial man in his sixties. He helped in the construction of Sonabia 2. The last years, he had been sailing as a crew with not-so-experienced sailboat owners.

A congenial man in his sixties. He helped in the construction of Sonabia 2. The last years, he had been sailing as a crew with not-so-experienced sailboat owners.

In open sea, Little Pig No 2 was good willing, not sea sick, took charge of the cooking. On the deck, he learned the basic maneuvers of non-furled sails.

However, he was technically very limited. He never learnt to sail with instruments and the autopilot was a personal enemy. A real danger during his watches.

And never ask him to repair something. His method was: “dismount everything then try to assemble it again” . Sometimes without success.

He was tired when we arrived in Argentina. He told me there about a hernia and he had a sore shoulder. He sailed down the roaring forties as a sick passenger, with a daily report to the Argentinian authorities.

He disembarked in Puerto Williams, Chile. He was examined at the Naval Hospital and luckily, the doctor found out that he had nothing serious.

A wildlife photographer in his forties, he had a short experience of sailing. However, he had previously sailed to Cape Horn on Sonabia.

A wildlife photographer in his forties, he had a short experience of sailing. However, he had previously sailed to Cape Horn on Sonabia.

From the beginning, Little Pig No 3 has been taking anti-seasickness tablets, and he did not stop for the next 2 months!

Living in a chemical cloud, he protected himself in his own filth. His cabin was a dark, smelly cave. He was himself dirty and very stinky. I had to oblige him to wash himself.

On the deck, he participated to the maneuvers, but not effectively: apprehension, chemical cloud, fear of getting hurt… After more than 6 weeks he confessed that he always had been scared of the water!

Arriving to Argentina, Little Pig No 3 stopped the tablets. He cleared his mind and behaved very well in the roaring forties, which were demanding: heaving-to 6 times for bad weather!

He disembarked in Puerto Williams after a quarantine, but did not make it to Antarctica: his partner could not join us in Chile on time.

Anyway, big hands for Little Pig No 3!

A man in his sixties, Big Bad Boar presents himself as an experienced sailor. He worked a few hours on the construction of the boat, interrupted by a judicial episode *.

A man in his sixties, Big Bad Boar presents himself as an experienced sailor. He worked a few hours on the construction of the boat, interrupted by a judicial episode *.

Big Bad Boar was not interested in the Atlantic Crossing, but he wanted to go to Antarctica. To my partner, he presented himself as the Providential Man. He joined us in Puerto Williams, Chile, while we were in quarantine.

The reality was quite different. Big Bad Boar was sick and apprehensive in the Drake Passage. In the Antarctica he had a panic attack that ended in a violent episode, related elsewhere

2021 07 02: Mutiny in the Antarctica, the nightmare of the family

Big Bad Boar was evacuated in the middle of Antarctica.

Big Bad Boar is now telling out his “exploits”. I reckon that he has a huge ego, but as for his honesty and mental balance, I am skeptical.

Unlike passengers, crews have to be skilled and mentally fit. We learnt it the hard way.

*Big Bad Boar´s name is Josu Guerra Tolosa, or Jesús María Guerra Tolosa. He served house arrest for harassing and threatening a woman.

February 10, 2022, on Sonabia 2, in the Antarctic Peninsula, the crew JGT suffers a panic attack that degenerates into a violent psychotic episode. He is evacuated the next day.

The short story is here: 2022 02 10 Mutiny in the Antarctica

For me (Eric, on board) it was stressful but somehow entertaining. For Maite, my partner it was a nightmare.

Since then, JGT (Josu Guerra Tolosa) tells of his “exploits”. He even contacted Maite to give his “version” of what happened. Forgetting that she heard his screams herself, on the satellite phone.

This is insulting, after what he put her through. Watch the following video and compare the proven facts with his “version”

Now, with Maite´s permission here is the true sequence of events, supported by satellite SMS between Sonabia 2, Maite and the Chilean Navy, mails and notes in the computer´s log file.

Note. All the supporting documents are available on demand, privately.

Sound tracks from Pixabay, FreeSoundLibrary, Mixkit

Sonabia 2 is equipped with 3 lifting rudders mounted at the stern.

The rudders are hoisted manually to change configuration. The operation takes about 5 minutes for each rudder. You also hoist the rudders to remove packs of seaweeds, for maintenance...

There are 2 safety mechanisms to block the rudders in low position (a blocking rope and a removable plate). In case of impact, the safety breaks and the rudder lifts. The damage is minor.

A single person can replace a rudder without help, boat in the water. Careening is also easy: you only have to lift the rudder

In case of broken rudder, the boat can sail with 2 out of 3 rudders, any of them The boat can even sail with a single rudder in case of emergency.

The rudders are made of laminated wood (epicea) with a protection of fiberglass epoxy. The underwater profile is straight, a little loss of performance, but a huge benefit in simplicity.

The architect´s proposal was 2 elliptical rudders. Good for performance, bad for maintenance. There were hollow rudders, a glass epoxy shell filled with epoxy foam. The construction is expensive and time demanding. At the time I also had to find a solution for maneuvers. High hull, rudders and propeller close to the stern: not good for maneuvers. A bow thruster was discarded (complication, cost, weak point in the hull). So I decided for a third rudder behind the propeller (a common patch in expedition sailboats). I was about to add a small rudimentary rudder, but an acquaintance remarked that building 2 or 3 identical rudders did not make a big difference. So, 3 lifting rudders. I discarded the elliptical profile but I kept the hollow rudder construction. During the first transatlantic sailing (2021), the rudders gave problems. Weak point at the waterline (my fault), deficient blocking system (architect´s proposal, but my fault: I had been warned against it). For the first antarctic trip (2022), I used emergency rudders made of plain, green wood 75mm thick, built by a friend at Puerto Williams (thanks, Pascal " El Shov"). They worked very well and they served as a model for the definitive rudders.

Photo fokker triplane: Don Bay, pinterest.

There were many cruise ships in Antarctica in 2022-2023.

In some spots several ships were waiting to disembark in turn (we, sail ships, avoid most of these spots).

70 cruise ships, 468 trips, 111.400 visitors: this is what the Antarctic Treaty allowed for the season 2022-2023

Since the season 2019-2020, the Antarctic Treaty allowed: 26% more visitors 79% more ships 61% more travels

Compare with small ships (sail ships and motor vessels below 70 persons): 34 vessels, 90 trips, 1299 visitors: this is 1.2% of the visitors.

Source: Antarctic Treaty database

The Antarctic Treaty delivers mandatory permits before the season. So we know how many visitors, boats and trips are allowed. Warning: the actual figures may be slightly different (2023 06 03: the figures for the season 2022-2023 are not updated yet). 1) cruise ships are not always full; 2) inversely some ships are not listed, for instance seen in the Drak: a ship with 2300 passengers, in Antarctica, another ship with 1950 passengers.

database - pre-season 2022-2023 pdf - list of ships database - pre-season 2019-2020 pdf - list of ships xls - lists of ships and totals

2023 02 12 - Paradise Bay

In a former post we presented our impact tests on several hull materials. We now analyze the results.

Strongest materials are in the top right corner, weakest are bottom left

From strongest to weakest

Plywood 22mm thick is typically used for the bottoms of hulls, sometimes for the sides.

It does not stand impacts. The material does not accept important bending, it breaks.

Special plywood (e.g. , marine), epoxy coating, etc. does not improve significantly the impact resistance.

The external glass epoxy protection does not improve resistance, it only prevents immediate flooding. Note that aramide is not much stronger than fiberglass, only lighter.

Note. with a glass coating on both faces, the plain plywood becomes a sandwich and the impact resistance increases markedly.

The aluminum alloy 5083 12mm thick is typically used for the sides of the hull, sometimes for the bottom.

It stands well impacts. Above some threshold, the impact energy is absorbed by the material, in the form of deformation and heat.

When the metal is thick (12mm in our test), there is no leakage. However I have seen aluminum hulls leaking after touching rocks.

The counterpart is that aluminum is quickly damaged by impacts (pokes, depression). As the impact energy increases the material is deformed beyond reparation.

Fiberglass epoxy 10mm to 15mm thick is typically used for sides and bottoms of hulls.

Glass epoxy planks 6mm and 8mm thick could stand the highest impact energy in our test. The material is elastic and flexes a lot without damage

However, flexible panels are not suitable for the hulls of cruising boats. Thicker panels, sufficiently rigid, are likely to stand higher impact energy, but when they break the damage may be important.

This material is used for the sides of Sonabia 2´s hull.

From interior to exterior: - plywood sandwich. 10mm plywood with 2mm of glass epoxy on both sides - PVC foam 30mm thick (bricks 125x25cm with glass-epoxy walls). - external glass-epoxy 4mm thick

This material stands well impacts, even better than aluminium. At the highest energy of out test, the external glass layer separates from the foam and the foam is locally broken.

The inner plywood sandwich and the external glass-epoxy layer are unaffected (see video). In other terms, there is no leakage.

Part of the energy is absorbed by the foam (local breakage) and the detachment of the external glass-epoxy. Both damages are easy to repair.

High latitudes mean ice, cold, no repair facilities, no rescue.

The hull must be strong, impact- and abrasion- resistant, adapted to cold and easy to repair at sea.

There is no magic material for high latitudes. Sooner or later, any material can be damaged, broken or perforated.

However, several materials provide an adequate safety margin, provided that they are adequately implemented.

2023 02 17 - Danco Island, at anchor. 3 knots current, icicles heavier than the boat bumping and scratching the hull.

2023 02 16 - Lemaire passage. Crossing brash at 3 knots.

“The hull material determines the robustness”

Not so. The thickness of the hull plates and the way they are supported are at least as important.

Compare two types of aluminum boats: the Vinson of Antarctica, designed for ice, has close-spaced stiffeners. The Strongall boats, designed for travel, have thick plates and no stiffeners.

“The more rigid the material, the stronger it is”.

Not so. In the Titanic, they used the best steel available at the time. In the cold, the hull plates became brittle.

“The harder the material, the stronger it is” .

Not so. Glass panels resist to scratches but they don´t stand impacts. Polycarbonate is easy to scratch but it stands strong impacts.

“Fiberglass is less robust than metal”.

Not so. Increase the thickness and you reach any level of robustness. And it is surprisingly long-lasting.

The professional fishing boats made of thick fiberglass are the best example. After 40 fishing seasons, their hull is still in good condition.

High ductility steel should be employed, e.g. quality H36. Otherwise the hull plates may break in case of impact. In addition, you need specific alloys for cold, otherwise the plates become brittle, e.g. CH36 or DH36. Advantages High surface hardness, i.e., abrasion and scratches resistant High mechanical strength, e.g., 21kg/mm2 to cause damage to stainless steel, 36kg/mm2 for H36 steel. Fatigue strength: good. Repeated stress like waves has little long-term effects. High stiffness,i.e., in theory, you can use thin hull plates and few hull stiffeners. About thickness Thin hulls are difficult to weld and they tend to depress permanently between stiffeners (the " hungry horse look"). Typical hull thickness for polar sailboats: lower limit 6mm, up to 15mm for extra resistance (e.g., MV Astra). Drawbacks Weight: steel is very heavy (density 7.80 to 7.85). For instance 6mm thick plates weight about 47 kg/m2. In light weather, a steel boat needs a lot of motoring, and a lot of fuel to move its weight. Only large sailboats (e.g. global challenge, 72ft) can overcome the weight handicap. Oxidation. Steel is prone to oxidation, galvanic, electrolytic, and ordinary rust. Steel needs a good protective coating and anodes. Repairs at sea. Submarine epoxy putty or fast underwater cement for small leaks, SOS for large holes.

Aluminum is widely used for expedition sailboats and fast service boats. The usual marine alloy is the 5083. Advantages Weight: aluminum is 2.8 times lighter than steel (density 2.66-2.8). Impact strength: very good. The plates bend, the bows twist but they generally remain watertight. However, no material is 100% safe. I have seen aluminum hulls with deep grooves and multiple leaking after touching rocks. Fatigue strength: good. Repeated stress like waves has little long-term effects. Other features Surface hardness: much below steel, similar to epoxy resins. The hulls often present scratches and pokes. Mechanical strength: high, slightly lower than steel, e.g., 19 kg/mm2 for aluminum vs. 21kg/mm2 for stainless steel. Stiffness: only 30% of steel, in other terms Aluminum is flexible. This means that the hull plates must be thick and supported (stiffeners). About thickness and stiffeners Typical thickness for strong expedition sailboats is 15mm at bottom. The plates weight about 40kg/m2. Given the relative flexibility and deformability of aluminum, it is safer to use close-spaced hull stiffeners. Drawbacks The aluminum is prone to galvanic and electrolytic oxidation. If there are too few anodes, the hull may be damaged in depth. Repairs at sea: like steel, submarine epoxy putty for small leaks. SOS for large holes.

Very strong boats can be constructed with fiberglass. For instance fishing boats made of thick fiberglass are in good shape after more than 40 years. Build quality is essential. Using chopped fiber instead of roving (woven), too much resin, dry spots, bubbles etc. cause weakness and low internal cohesion. Advantages Weight: typical fiberglass composites are 5 times lighter than steel, (density 1.70 vs. aluminum 2.8, steel 7.8). Fiberglass allows for performant boats (light-medium displacement hulls). Low maintenance, easy repair. New layers of fiberglass, sand milling, and the hull is as good as new. Other features Surface hardness: similar to aluminum for epoxy resins, poor for polyester (about 8 times softer). Impact strength: variable. With a well-built, thick hull, the damage will probably be limited to delamination and/or a small hole. For poor quality hulls, there will be extensive delamination, large fractures and/or large holes. Mechanical strength: high. Fiberglass composites can stand higher loads than steel and aluminum, provided that the load is static (see below). Stiffness: low (40% of aluminum, 10% of H36 steel). Fiberglass is very flexible. You need thick hull plates, supported by stiffeners. About thickness Robust expedition sailboats typically have hulls 15mm to 20mm thick at bottom, thinning progressively towards the top. Thickness brings rigidity, robustness, resistance to fatigue and most important safer behavior in case of impact. Drawbacks Bending strength: poor. Fiberglass do not stand excessive bending. Fatigue strength: poor. Repeated efforts like waves weaken the hull. In both cases, the solution is: thick and rigid hull plates. No bending, no fatigue. Repairs at sea. Submarine epoxy putty for small leaks, plates of plywood, sikaflex or similar, and conical screws for large holes.

In general epoxy resins are mechanically stronger than polyester and their surface hardness is about 8 times higher. However, the main difference for high latitudes is the water resistance. Whereas epoxy is watertight, polyester absorbs water. This means that deep scratches have no effect on epoxy but cause internal damage to polyester, e.g., osmosis. Note: vinyl ester is a good substitute for polyester: although less strong than epoxy it is water-resistant... and cheaper.

Carbon fiber is superior to steel and any other material in terms of mechanical strength, fatigue strength, and weight. It allows building stiff and light hulls, perfect for ULDB (ultra light displacement boats). Drawbacks Carbon would be the perfect material except that it does not stand impacts. They generally cause extensive delamination, sometimes beyond repair. At higher impact energy, the plate explodes.

In a sandwich, two thin layers of a strong material (e.g., fiberglass) enclose a thick core made of material like balsa wood, rigid foam... Sandwich materials are very light and easy to repair. Their stiffness can be arbitrarily high: the thicker the core, the more rigid the sandwich. Their surface hardness is that of the resin, generally epoxy. Drawbacks The impact strength is low. Under an impact, the core is often crushed and the skins "peel off", they separate from the core. In addition, because the skins are thin, deep cuts and scratches may reach the core (damaging for balsa wood, hollow honeycomb etc.).

In general, compared to steel, the mechanical strength of wood is less than 40%, the bending stiffness less than 10%. Note that these figures vary widely with the type of wood and the quality of the planks. This does not mean that wood is a weak material, just that the planks have to be thick (e.g., 40mm) and the stiffeners closely spaced. Drawbacks Possible flooding. The pressure of the ice can move the planks and damage the joints. Impact strength is rather low. Whatever its thickness, wood tend to break (tested up to 60mm thick). The wood must be protected from parasites, even in cold waters. So you need facilities for periodic hull maintenance, cleaning and coating.

Plywood is light (typical density 0.5), relatively stiff, and resistant to mechanical fatigue. It is a good material to build ultra light to light displacement boats. Drawbacks Impact strength low. Plywood does not stand impacts whatever the thickness (tested). Under impact, it breaks and there is a flooding. The surface hardness is low. Because the inner layers of plywood are generally soft woods, there may be deep scratches External protection (fiberglass or aramide) prevents from scratches and immediate flooding, but it does not improve impact resistance (tested). A double protection, inside and outside, improves the impact strength of plywood. It becomes impact-resistant (tested), see below why. Repairs at sea: even for large holes, a piece of plywood, sikaflex or similar and conical screws.

Laminates are composed of multiple layers (plywood, wood, rigid foam..) separated by layers of fiberglass. For instance large unsupported curved beams can be made of multiple layers of wood alternating with layers of fiberglass. The fiberglass layers support the internal stress that appears during bending, whereas a plain material would break. The external layers of fiberglass increase the stiffness, like in a sandwich. Advantages Stiffness: high, similar to sandwiches. The thicker, the more rigid. Mechanical strength: high. Similar to fiberglass for axial efforts, but a laminate also stands transversal efforts and twisting. Impact strength: high, and safe behavior (tested). The multiple layers of fiberglass prevent flooding. Low maintenance and easy repair. Similar to fiberglass. Other features Surface hardness: that of fiberglass-epoxy, i.e. similar to aluminum. Weight: depends of the number and type of layers, but in general rather light, a mix of the weight of plywood and fiberglass. Drawbacks Cost of production: many heterogeneous layers mean a lot of work Repairs at sea. Submarine epoxy putty for small leaks, plates of plywood, sikaflex or similar, and conical screws for large holes. An example of laminate for high latitudes Sonabia 2 uses the following: internal glass epoxy 2mm thick, plywood 10mm thick glass epoxy 2mm thick, PVC foam 30mm thick and external glass epoxy 6mm at bottom to 2mm (19.5mm at the bow)

Summary of important features.

Stiffness / flexibility The stiffness (Young modulus) characterizes the force to apply to stretch or compress the material. What does it mean? Any material is somehow elastic: it can stretch or compress before returning to its initial length. The Young modulus measures the effect of axial forces on the length of the material. The Young modulus allows calculating the bending stiffness, i.e. how much a plate of the material bends under the effect of transverse forces. The Young modulus also tells us how thick the hull must be to reach a desired stiffness. Against intuition flexible materials can make rigid hulls, just by increasing the thickness. Mechanical strength The mechanical strength characterizes the pressure to apply to break the material (tensile strength, compressive strength) or cause permanent damage (yield strength). What does it mean? It defines how much the material resists to traction or compression. Indirectly it allows calculating the bending strength, i.e., the transverse effort that will cause a permanent damage The mechanical strength is independent from the stiffness. Some flexible materials are strong whereas some stiff materials are not. Fatigue strength The fatigue strength characterizes the amount of repeated efforts that a material can support before break or permanent damage. What does it mean? The fatigue strength is expressed as a combination of amplitude and repetitions but it basically characterizes a lifespan. For instance a hull plate is exposed to waves. At each wave, although it is hardly visible, the plate bends and straightens. This causes microscopic damage (¨fatigue cracks¨) that have a cumulative effect. However, it is possible to build fatigue-resistant hull plates with short-living materials: increase the thickness and place stiffeners to reduce the bending. Impact strength The impact strength characterizes the impact energy necessary to break or damage permanently the material. What does it mean? It represents the capacity of the material to stand instant, locally concentrated efforts. Impact strength is measured by means of destructive tests where the parameter is the energy, e.g., dropping a weight from a given height. The impact strength increases with the mechanical strength, but you cannot say much more: the type of effort is different. For instance carbon fiber has a high mechanical strength but a low impact strength. Energy absorption The energy absorption characterizes how a material can absorb energy without breaking. What does it mean? During an impact, the more energy is absorbed, the less energy is left to cause complete destruction. In materials like aluminum, high ductility steel, kevlar (aramide), the energy is used to deform the material before the rupture. On the contrary, materials that do not absorb energy break immediately, e.g., carbon fiber, high grade steels, plywood... Rupture behavior The rupture behavior characterizes what happens when the material breaks or is permanently damaged. There are several types of rupture behavior: deformation, internal damage, through fractures. The damage can be local or widespread. Rupture behavior is known by real experience and experimentation, not by theory. However there are 4 rules of the thumb: 1) ductile materials are first deformed; 2) heterogeneous and composite materials are first damaged internally; 3) rigid materials break badly; 4) all materials break completely under high energy impacts. Surface hardness The surface hardness characterizes how the material resists to penetration and cuts. What does it mean? hard materials resist well to scratches and abrasion whereas soft materials are damaged whatever the superficial coating (primer, painting, anti fouling). There is no universal scale but the following ranking is safe: 1) iron(far ahead) 2) aluminum and resins 3) wood and 4) plywood. For each material there are many variations (alloys, types of resin, hard vs soft wood...). Finally, the resin is determinant for composites and impregnated wood and plywood (impregnation means that the resin penetrates in depth). Epoxy resins provide a surface hardness similar to aluminum alloys. Resistance to cold The resistance to cold characterizes how the material stands direct exposure without protective coating. The hull material is exposed to low air temperatures and to cold water because of the cuts and scratches caused by ice. Some materials become brittle in cold, e.g., high grade steels wood and plywood if they are soaked and the internal water freezes (e.g., deck). Ease of repair The ease of repair covers two aspects: emergency repairs and restoration of the hull in its initial state. Emergency repairs are relatively easy when the damage is local. Stop the flooding and patch the material. Emergency repairs turn difficult when the damage is widespread. Thus materials with a bad rupture behavior like carbon should be discarded. Restoration is easy for composites (sandmill and add new layers), plywood (scarf) and wood (replace the planks). Restoration is more difficult for metals: the damaged plates are weakened and should be replaced (cut and weld). Using putty is merely cosmetic. Weight In modern yacht design, the intrinsic weight of the hull material is determinant for the architecture and the performance of the boat. This is why steel is generally discarded. However for high latitudes the significant factor is the weight of the hull that provides sufficient strength. This takes into account the density of the material, the plate thickness and the stiffeners.

January 2014 – The hull of Sonabia 2 was already shaped with 10mm plywood, but the composition of the remaining layers had to be determined. We were skeptical about the architect´s proposal.

Thus we conducted impact testing on different combinations of layers, comparing to reference materials, aluminium, plywood, fiberglass epoxy…

We destroyed a lot of samples to determine an adequate composition of layers.

Warning. Before watching this video, keep in mind that impact resistance is only ONE factor among others for the choice of hull material.

Weight, stiffness, flexural strength, mechanical fatigue resistance, surface hardness, ease of repair are equally important.

Antarctica February 5 to March 2, 2023 6 persons,1484 nautical miles (nm), i.e., 2750 km. Total fuel consumption 671 liters, 232 engine hours. Averages: 2.88 L/ engine hour, 0.45 liter / nautical mile, 0.38 kg/nautical mile, 0.063 g/ person x nm

This corresponds to a very low carbon footprint: why?

On modern cruising ships, hybrid propulsion (electric motors + fuel or GPL generators) consume and contaminate less than classical heavy fuel engines [2].

Consumption figures are not public, however, here are safe estimates

For a small passenger ship, 200 passengers,in economical mode (observed on AIS: 13 knots in Antarctica) Pessimistic estimate : 100 tons of fuel or equivalent per day. Source [1]. 100 tons per day means 4167 kg/hour, 320 kg/nm, 1.6 kg/passenger x nm. Optimistic estimate: 20 tons of fuel or equivalent per day. Source. Consumption of modern cargo ships [3, table in 1], equivalence cargo ships - cruise ships of similar displacement, using a conversion factor 40% (gross tonnage vs. metric tons; data of several cruise ships available on the web) 20 tons per day means 833 kg/hour, 64 kg/nm, 320 g/passenger x nm.

Clearly, passenger ships are not environment – friendly, even with modern propulsion systems. Actually, passengers ships consume more than cargo ships, for 2 reasons

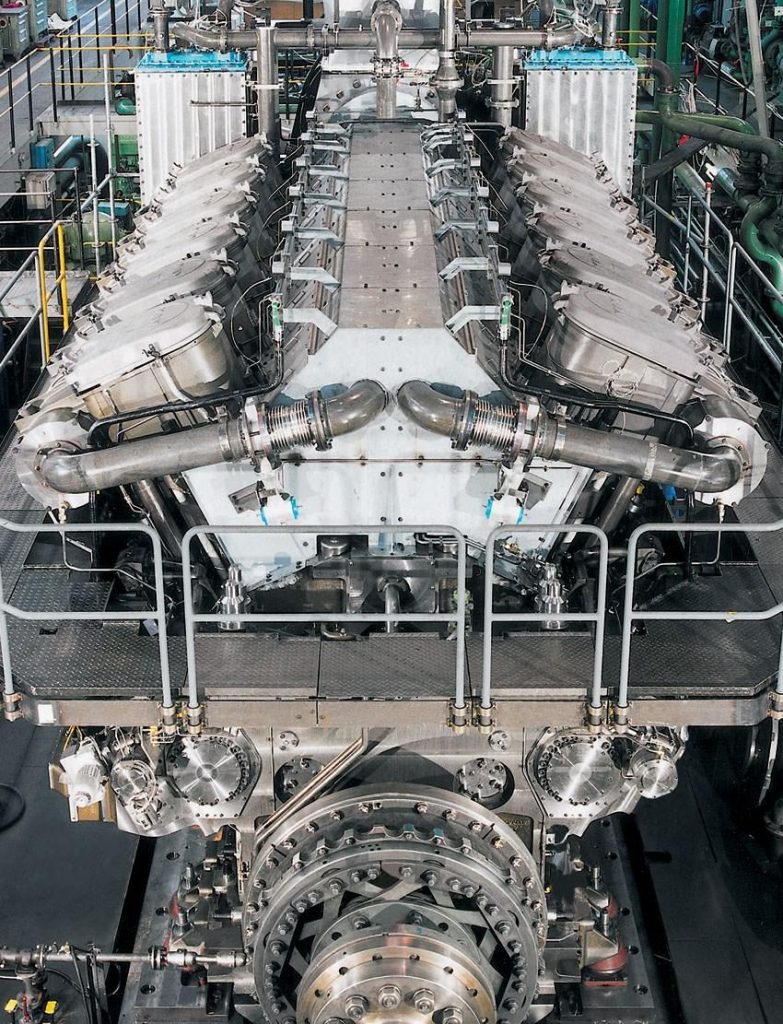

Sonabia 2: engine, Nanni 85HP, Euro norms.

Sonabia 2: engine, Nanni 85HP, Euro norms.

Cruise ship: example of engine [2]

Cruise ship: example of engine [2]

Sources: [1] https://www.marineinsight.com/know-more/how-much-fuel-does-a-cruise-ship-use/ [2] https://www.cruisemapper.com/wiki/752-cruise-ship-engine-propulsion-fuel [3] https://maritimepage.com/fuel-consumption-how-much-fuel-cargo-ship-use/ [4] https://www.cruisemapper.com/wiki/753-cruise-ship-sizes-comparison-dimensions-length-weight-draft

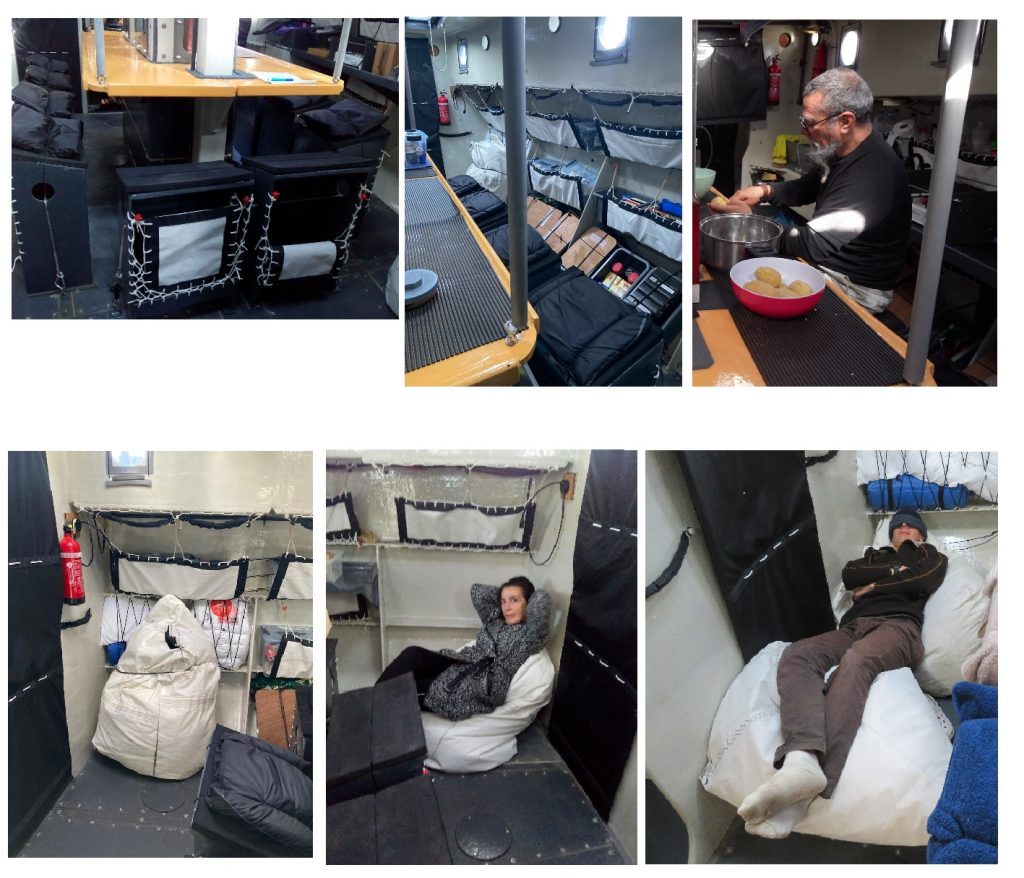

We hesitated between two styles. Finally we decided to keep it simple.

Bar table and stools to eat or work.

Stools: made of plywood, anchored to the floor. Used for storage.

4 bean bags to relax or sleep.

Bean bags: made of recycled sails. filled with pillows.

What more do you need in an expedition boat?

What more do you need in an expedition boat?

Pictures: dreamtime, aliexpress, decoración vertical arquitectura.

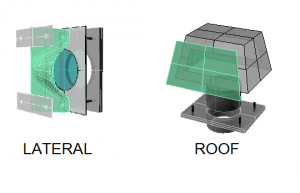

2023 04 29 – In Sonabia 2 there are 26 ventilation holes.

They generate local ventilation for each room.

They generate local ventilation for each room.

The local ventilation dries the cabin

The local ventilation evacuates damp air from each cabin. Even if there is a cold air inlet, the thermal sensation is better because the ambient air is more dry.

In the high latitudes, without adequate ventilation, it is frequent to see water dripping from the cold surfaces during the night.

This humidity comes from 1) the atmosphere (rain, fog, etc.) 2) cooking (gas combustion produces steam and CO2) and 3) mostly from human respiration.

Does the local ventilation work?

See by yourself. After 1 month sailing in Antarctica we cleaned the two front cabins, each occupied by one person.

In the port cabin, seldom ventilated, we collected more than 1/2 liter of condensation water .

The starboard cabin, ventilated every day, had no condensation water.

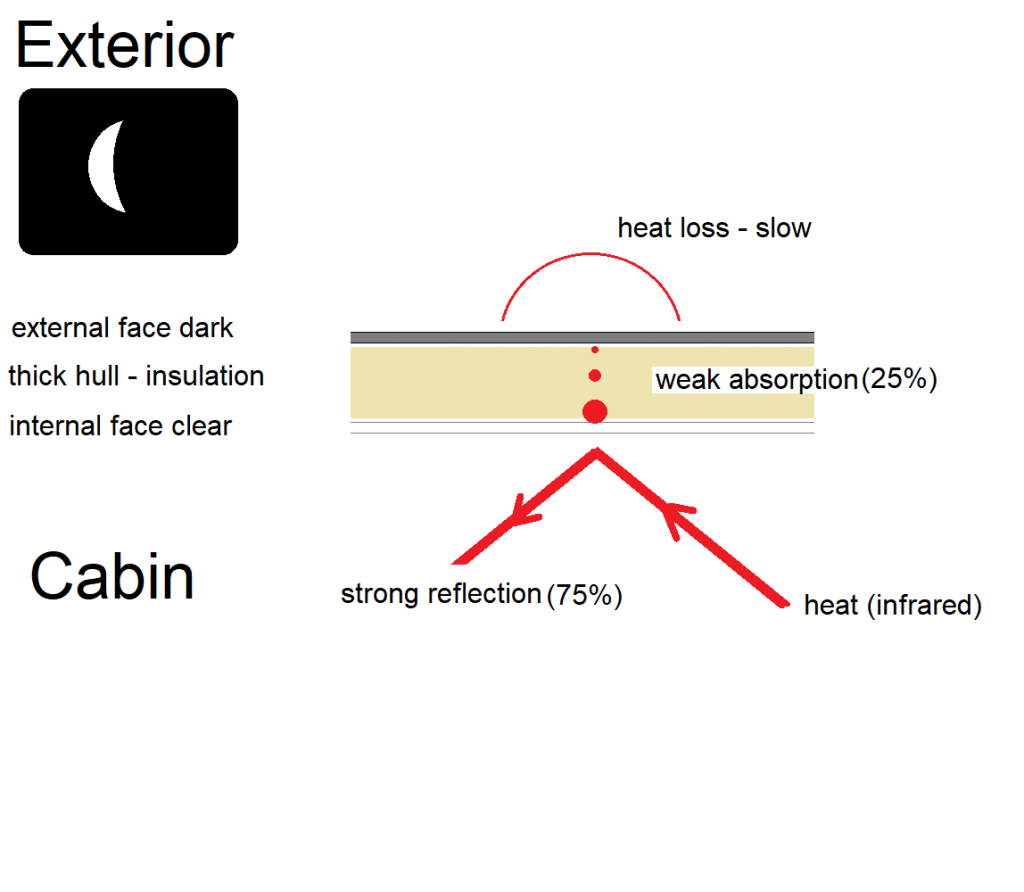

The first thing you notice on Sonabia 2 is its color: Hull and deck are a dull dark grey. Sonabia 2 looks like a tank.

Explanation: heat with solar radiation during the day, release the heat slowly during the night. See below.

By day

The external skin of the hull is a matte dark gray, it has a low albedo. It absorbs about 75% of the solar radiation and reflects only 25% (these figures are only illustrative). Hence about 75% of the solar radiation is absorbed by the hull which in turn radiates heat into the cabin.

By night

The internal skin, light grey and polished has a high albedo. About 75% of the infrared radiation (heat) coming from the cabin is reflected. Only 25% of the energy escapes through the hull. The insulating hull material (thick PVC foam) reduces further the heat loss. In practical terms, by day the cabin warms up and it cools down slowly after nightfall.

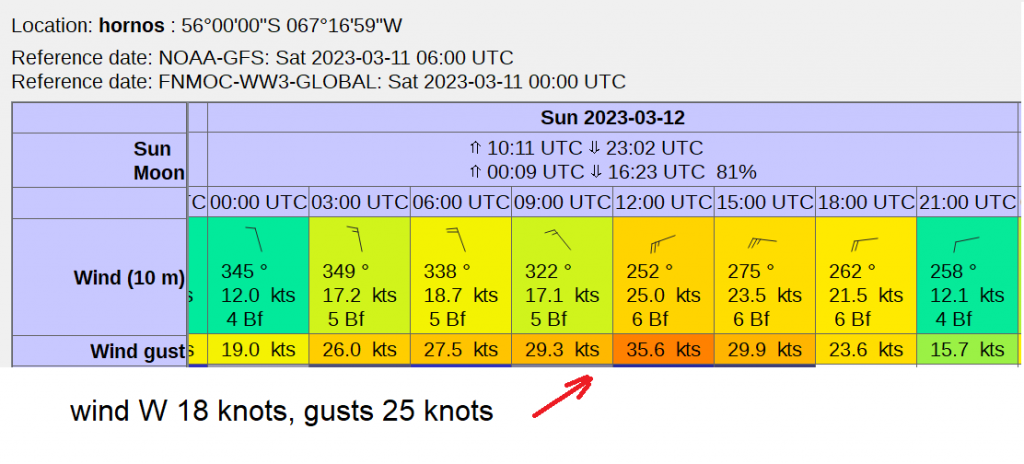

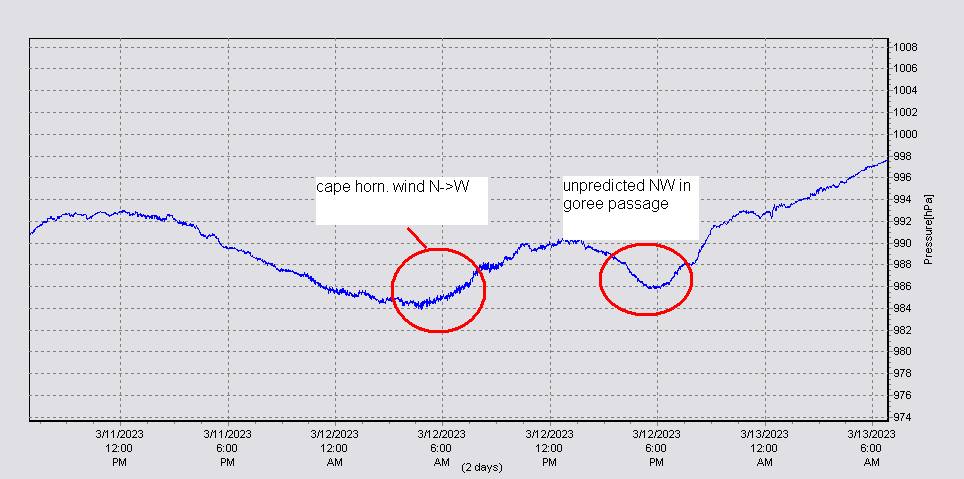

2023 03 12 – Cape Horn at sunrise. The timing was precise. The weather forecast predicted a change of wind around 09:00AM (local time)

So we sailed towards the south during the night with a back wind. We monitored constantly the barometric pressure.

So we sailed towards the south during the night with a back wind. We monitored constantly the barometric pressure.

At sunrise we were in position, NW of Isla Hornos. The wind changed as expected. We crossed Cape Horn towards the east with a back wind, about 18 knots with gusts up to 25 knots.

2022 12 13 – SV Sonabia. Cape Horn under staysail and reefed main sail.

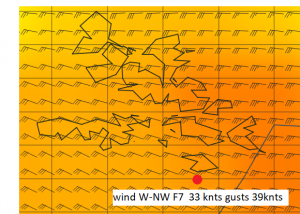

A calm night at anchor in Caleta Maxwell, Hermite Island near Cape Horn. Sailing when a front arrived. The wind came from W-NW and within a few minutes it increased to Force 7, gusts 35 knots and more.

Caleta Maxwell in the morning, the same day

2023 02 16 – Sailship Sonabia 2, Antarctica, Lemaire Passage

Home – Antarctica – Contact

Sonabia 2 sailing in Antarctica. Gerlache Strait in the mist

Home – Antarctica – Contact

On 2022 11 21, 17:49 UTC time, Sonabia rounded Cape Horn for the 25th time.

The first Cape Horn was in Dicember 2012.

After 3 years, Sonabia sailed back to Puerto Williams in 2016 and was present for the 400th anniversary of the discovery of Cape Horn (Caap Hoorn).

From then, we sailed around Cape Horn during the seasons 2016 and following.

In March 2020, the last trip of the season was cancelled for COVID (Lock down of Navarino Island).

After two years, we could sail again to Cape Horn.

To put things in perspective, Sonabia is a – relative – new comer, some skippers rounded Cape Horn more than 100 times.

However 25 successes out of 26 attempts is a respectable score.

Alone in the Antarctica with a psychotic, violent crew, armed with a big knife.

Happy end, don’t worry.

*NEW *

The 3 Little Pigs and the Bad Big Boar, or how NOT to choose your crew.

February 2, 2022: Sonabia 2 departs from Puerto Williams towards Antarctica. Aboard Eric (captain) and JGT (crew).

February 10, Melchior Islands, Antarctica. We are about to leave a mooring. JGT has a psychotic episode.

“I want to disembark now – I want to disembark now, turn back now – etc.”. No way to reason with him.

While I am recovering a mooring line (rope tied to a big rock), JGT throws overboard the scythe and the machete used to clear the kelp (sea weed).

“I want no weapons abord!” he yells, “I don’t trust you and I dont trust myself”.

Well, HE is armed with a big knife that he brought aboard.

JGT becomes more and more agressive and tries to intimidate me: he threatens me and searches for physical contact.

I call Maite (my wife) by satellite phone. If I don’t contact her within 24 hours, she will report to the Chilean Navy.

I tell this to JGT. My life insurance, I say. JGT’s answer: “Good, if I prevent you from calling they will come for us”.

Not really what I expected. Therefore I contact directly the Chilean Navy by satellite phone and I inform on a mutiny.

From now on the Chilean Navy will keep permanent contact by satellite phone and keep my wife informed.

Every time I am on the phone, JGT yells as a rabid donkey, almost covering my voice.

Sorry for the comparison. Donkeys are sweet.

At some point, JGT prevents me from reaching the pilot table. He seems busy taking pictures, writing notes… Obviously not steering the boat.

Either JGT wants to take control of the boat or he wants to cause damage, so that he will be rescued. And as a bonus, he wants to make me responsible of whatever happens.

Paranoia? NO. In a former argument (February 8) he repeated several times that whatever mistake he did was my fault because I was the captain, that if I could not prevent him from making errors I was no captain.

This sounds weird, but legally he is right… Except that I declared mutiny. In this case the captain is no longer held responsible. He is the only responsible for his acts.

JGT blocks the access a first time. After a few minutes he reluctantly steps back and I can use the pilot table.

A moment later, he does worse. He blocks the entry of the cabin and pushes me outside.

First physical assault. Enough! The boat is without pilot in a dangerous, narrow bay (“the Sound”) .

I grab him back, prevent him from pulling out his knife and throw a couple of punches.

I have to use persuasion to cool him down (to be precise I use a neck lock and a mooring rope). After some time, he gives the signal that the struggle is over.

From now on he is agitated but no longer aggressive. Instead, he takes selfies of his bleeding nose.

Selfie by JGT

Selfie by JGT

I leave him make radio calls. He calls any boat around for help. However, I keep the satellite phone with me. Safer.

While we circle around Melchior Islands waiting for instructions, the Chilean Navy dispatches two sailboats to assist us.

The initial plan is to escort us towards the Navy Station Gonzalez Videla. However JGT makes a fuss, he does not want to be in the hands of the Chilean Authorities.

So I accept a B plan, and we meet the sailboat Y between Melchior islands Eta and Omega. We have to sail in a thick fog.

The fog and the rocks unreported on the nautical chart make things more interesting, thank you JGT.

We reach the meeting point, raft the two boats and JGT jumps aboard the Y.

JGT expects to sail back to Puerto Williams on the Y. No way. The crew does not want JGT aboard. As an information, there is a neuropsychologist aboard, and she assesses his mental state.

Instead, the Captain of Y uses his tender to drop JGT in an empty Argentinian station on another island, 2 miles away. He will spend the night there.

First thing, he confiscates the knife.

Next day, the Argentinian vessel Bahia Agradable picks JGT up (the Argentinian and Chilean Navy patrol in turn).

After I got rid of JGT, I sailed deeper into the Antarctica, and back to Puerto Williams, single handed. This was a wonderful trip, and Sonabia 2 behaved very well.

On the way back I stopped at the Chilean Station Gonzalez Videla. It was the opportunity to meet these nice people and to thank them personally for their support.

His name is Josu Guerra Tolosa (his true name is Jesus Maria Guerra Tolosa) . He lives in Hondarribia, Spain, and owns the sailboat Spirit of Anuk.

When I wrote this post, on April 24, 2022, I wanted to keep this anonymous. However, I saw on April 29 that JGT published an article in a Basque Journal, with names and personal data.

So be it.

In his version, he is the hero and the victim. He mixes up facts and dates, there are omissions and invents. He does not care about contradictions.

However the article gives insights into his state of mind. This confirms 100% what we (Maite and I) analyzed afterwards.

1) I did not know well JGT and I only sailed a few times with him.

The guy helped spontaneously for the construction of Sonabia 2 (he worked 64 hours). Out of gratitude, we invited him to sail to Antarctica.

Also we wanted to assess his potential as a crew for future trips. He was very proud of his sailing experience.

2) A high self esteem but no high latitudes experience

He writes (translated from Basque) “I am a merchant marine officer, a high seas skipper, a professional sailor, I am not a beginner, I am a full-fledged sailor “

However he never sailed in the roaring forties, less in the screaming fifties or the Antarctica. Sailing with tourists in the Mediterranean Sea does not prepare you for this.

3) A lesson giver that does not accept his own ignorance

Before we sailed JGT gave me an extensive lecture on the theme: “I always respect my crewmates, I never yell, etc.”.

Point taken, I am rather foul mouthed. When dealing with him, respect and no yelling .

However, at the first observation I did him (with respect, as he demanded) he exploded and threatened to disembark.

Departing from Puerto Williams, he did a fancy maneuver to cast off the mooring ropes. Fancy but unsafe in windy conditions. I told him so. From his viewpoint, this was an unacceptable criticism.

I did not react to his outburst and this was a mistake. I should have turned back to disembark him immediately. Later, it was too late.

The trigger of his crisis was another observation, this time in the Antarctica.

4) The fear of the Drake Passage and the Antarctica

The weather was strong in the Drake Passage and we found unfriendly easterly winds in the Antarctica.

Nothing exceptional but JGT was sick during most of the Drake crossing. After that, he started to mess up his maneuvers.

Confirmation. He writes (translated from Basque) “Antarctica is not my landscape (…) Everything there is white and gray. It’s an incredibly harsh environment (…) Ice everywhere, even in the water. If you hit these blocks… And on the boat, with the heating on at all times, with gloves at all times (…). Now, it’s been a tough challenge! Cross the Drake Passage (…)”

Elsewhere he writes (translated from Basque) “I think Eric gets especially nervous when he senses that the weather is going to get worse, and maybe that’s why..”

A typical inversion of roles. I have a bit of experience in the high latitudes (including a former single handed sailing to Antarctica, 24 sailing expeditions to Cape Horn etc.). Guess WHO gets nervous.

5) Poor understanding of the sailing conditions

JGT has a poor understanding of the weather in high latitudes and the constraints it imposes on the navigation.

This was clear right from the start. In Puerto Williams, when all the skippers could see an obvious weather window to cross the Drake , he only saw heavy weather.

At some point during his crisis he said that he was unable to steer the boat back to Puerto Williams. This was honest.

Combine a lack of understanding, the stress and the refusal to accept his own ignorance and you have the conflict that triggered the crisis.

6) The triggering conflict

February 8, 21:30. At 19:00 I went to sleep and I asked JGT to wake me up at 21:00. The wind was expected to turn and as a skipper it is my role to monitor this.

When I woke up – by my own – at 21:30 the wind had already changed. The waves were against us and the speed had dropped from 6-7 knots to 3 knots. Leeward, Brabant Island and its walls of ice.

Without entering into details, the rest of the navigation depended on the timing: we had to maintain our speed.

JGT was watching the nautical chart, doing nothing. I took his place at the pilot table, opened the throttle and the boat recovered her speed and her initial course.

I made him a clear criticism: his role was to wake me up. No way. He kept saying that he “did me a favor” by not waking me up and the change of wind was “nothing important”.

I tried very hard to keep my temper, but HE exploded. Among other things he repeated many times that whatever mistake HE did was my fault , as the captain, and that if I could not prevent HIM from messing things up I was no captain.

7) My lack of patience and diplomacy

I have problems with incompetence and stupid discussions. They often go together.

When the job is done, everything is fine. Screw things up, start a pointless argument and we are in trouble.

Also, I admit that I cannot make a clear difference between diplomacy and hypocrisy. Not good for resolving conflicts.

When JGT yelled at me, spitting in my face and pointing his finger at my nose I did not accept it an I yelled back.

I could not help it, even if it is pointless to argue with donkeys.

After that, It was clear that JGT was useless as a crew. I just ignored him. At least for a few days, until the conflict cools down.

8) Planned violence

This was too much pressure for JGT. He could not stand to be ignored, he had no patience to let things cool down. He was about to become violent.

He writes (translated from Basque) “It’s not easy to handle that. Think about it, you are in Antarctica, isolated, with no sailboats around. I feared that the only way to handle the situation (…) was the use of force”.

This confirms what he yelled when he threw the cutting tools overboard: “I don’t trust you and I don’t trust myself”

Afterwards, I learnt that health professionals always consider the possibility of violence during psychotic episodes.

9) Two crew mates: risky

A crew of 2 persons only works if they know well each other.

I already had a crew mate that became nervous and touchy (but not violent) under the effect of anxiety. Pity I did not remember this before we departed.

With 3 or more people aboard, JGT would have been easier to control, physically and/or chemically. And all this mess would have been avoided.

10) Psychotic and panic attacks are common at sea

Afterwards, we reckoned that psychotic episodes and panic attacks are frequent at sea.

In her book Ocean Scrapers, about Terra Nova fishermen, Anita Conti relates that a crew went mad and threw his own bed’s planks overboard.

This is the reason why the Spanish Hospital Ships that accompany the fishing floats have contention rooms (cells).

In addition, the high latitudes may worsen things. I personally knew four boats where such episodes occurred (now five). JGT is only the second person that became violent.

Next time, we will select carefully the crews. Not on the basis of their CV, on the basis of their attitude.

Sonabia 2 was launched on 2021 07 29 at Socoa, Iparralde, France. She is an expedition boat for the Great South (Cape Horn, Antarctica)

First test under sail on 2021 08 03 at Hendaye, France. Wind 6-8 knots, no waves, no current.

Sonabia 2 sails swiftly, I expected a brutal boat. In fact she is as smooth as a kitten.

Performance: true wind: 6.5 to 6.9 knots , speed 5.6 knots (close beating), 6.2 knots (open beating).

Not bad for an expedition boat! Configuration: main and genoa 110m2, load~12.5 tons, keel down, 3.4 tons, draft 2.95m).

Sonabia 2 was launched yesterday in the port of Socoa, Iparralde, France (Basque Country).

Tricky, given the size of the boat, the narrow access and the shallow port, but everything went well, thanks to the Chantier Naval de Socoa (special thanks to the former manager, VF).

Then sailing with engine to Hendaye, where Sonabia 2 will be during the next weeks.

Program: extensive testing. Then if everything goes well, Cape Horn and Antarctica.

Almost 8 years since the start of the work. Special thanks to all the friends that helped us along the project, PC, OM, CT, JMA, JGT, PL, C&MP, MB and many others.

courtesy Sandrine

courtesy Sandrine

courtesy Teresa, Juan

courtesy Teresa, Juan

courtesy Thierry

courtesy Sandrine

courtesy Sandrine

courtesy Thierry

courtesy Thierry

2018 12 21 – Departure from Puerto Williams. We stop in Puerto Toro for the night

Picton Channel. Courtesy Jerry Swift

Picton Channel. Courtesy Jerry Swift

Puerto Toro. Courtesy Peter Goodier

2018 12 22 – Anchored at Caleta Martial, Herschel Island, Wollaston Archipelago. The wind is increasing, gusts above 45 knots. We wait.

2018 12 23 – 0600 We sail around Cape Horn during a short period of calm. Residual swell ~3m

Cape Horn. Courtesy Jerry Swift

Cape Horn. Courtesy Jerry Swift

2018 12 23 – Back to Caleta Martial. Under engine, the wind is building up fast. During the night, gusts above 50 knots. We wait again

Caleta Martial, S/Y Vahiere in 40 knots. Courtesy Jerry Swift.

Caleta Martial, S/Y Vahiere in 40 knots. Courtesy Jerry Swift.

2018 12 14 – At 1900, we head north towards Puerto Toro and Puerto Williams. The wind has decreased to 25 knots, gusts above 30 knots.

Jerry Swift’s paper: www.unmondedaventures.fr

On January 29, 1616 Cape Horn was discovered by Willem Schouten and Jacob Le Maire on the vessels Eendracht and Hoorn. The Cape was named for the city of Hoorn, in Netherlands.

400 years later, the Chilean Navy celebrated the event, and the sailship Sonabia was invited.

Carlos Guevara, Chilean Photographer with his wife and daugther, Sylvie, Damien were the crews of this nice trip.

Carlos’s account of the event (in spanish): Navegando a vela en Cabo de Hornos, una aventura para el recuerdo.

Photos courtesy of Carlos Guevara Vivanco.

Photos courtesy of Damien Lochon

2020 03 09, Puerto Williams, Cabo de Hornos, Chile

12:30 – A whale is grounded in Seno Lauta, in front of the Micalvi Yacht Club, right next to the Sailing Yacht Sonabia.

It is a sei whale, 12m long or more. She is bleeding. The tide is low, she cannot pass.

We move 3 boats away to free the passage. A moment later she manages to turn back and swims freely but she grounds again, on the other shore of the Seno Lauta.

Killer whales where patrolling and they attack. The whale tries to escape but she cannot. At 17:00 she is dead. The tide is almost high, she is below water. The orcas keep on devouring her.